C & D

The ETL Model C & D Tube End Form Machine is designed and manufactured for the of ‘sizing’ and manipulation of thin wall (up to 3mm wall thickness) tubes.

The ETL Model ‘D’ model is a basic tube end forming machine for either expanding or reducing, using segmented tooling it can also accept tooling heads for slotting, piercing or notching.

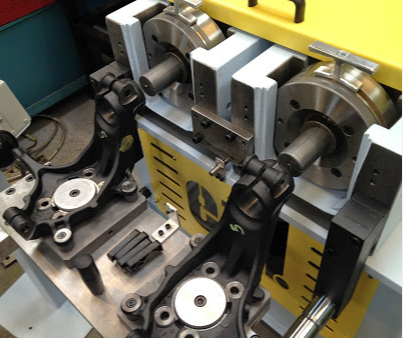

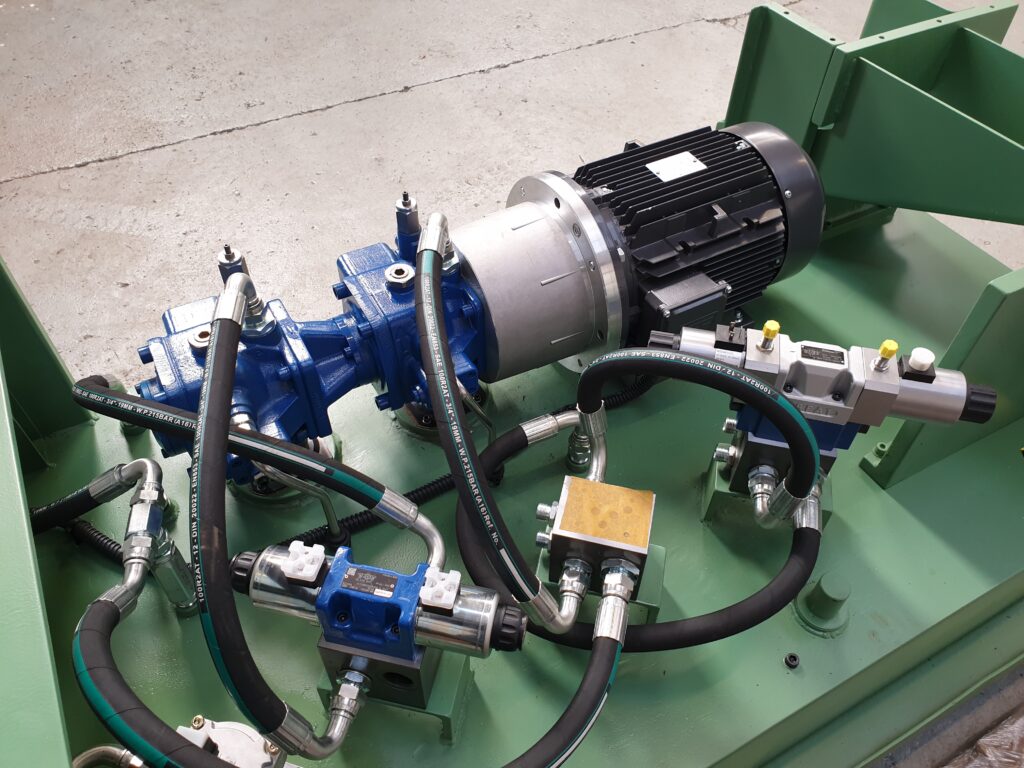

The machine is a compact, self-contained unit with the motor, drive and all hydraulic components mounted on top of the oil tank for ease of access. Above this is a top plate and two C type heads. Each head has a single horizontal hydraulic ram with micrometer adjustment for stroke length. The drop-in tool nest ahead of the ram was designed to accept all standard C type tooling.

The two machine heads can be operated individually or in sequence but NOT simultaneously. They can also be operated in 3 steps to give gradual sizing over 3 hits per cycle to help prevent splitting of stainless steel components during the forming operation.

IO

The ETL ‘IO Type Machines’ are required when a higher accuracy sizing is required. The machines have a dual action cylinder which applies a separate and individually controlled force to each element of tooling, the inside expanding fingers and the outside reducing jaws. The machine and tooling are capable of calibrating, expanding, reducing and producing annular/emboss forms.

Ten operating sequences are provided by the thumbwheel, and understanding them will help you get the most out of the machine. For example, a sizing operation which requires a close tolerance inside diameter choose a sequence in which the Outer Ram returns before the Inner Ram. For critical Inner-with Expansion.: the sequence would be, the inside fingers would expand to the setting of the stop nut, then the outside jaws would close to the stop nut , or else close down to squeeze the outside of the tube onto the fingers (both should be set to occur at the same time.) After a barely visible delay the outside jaws should retract followed by the collapse of

the inside fingers.

C-Frame

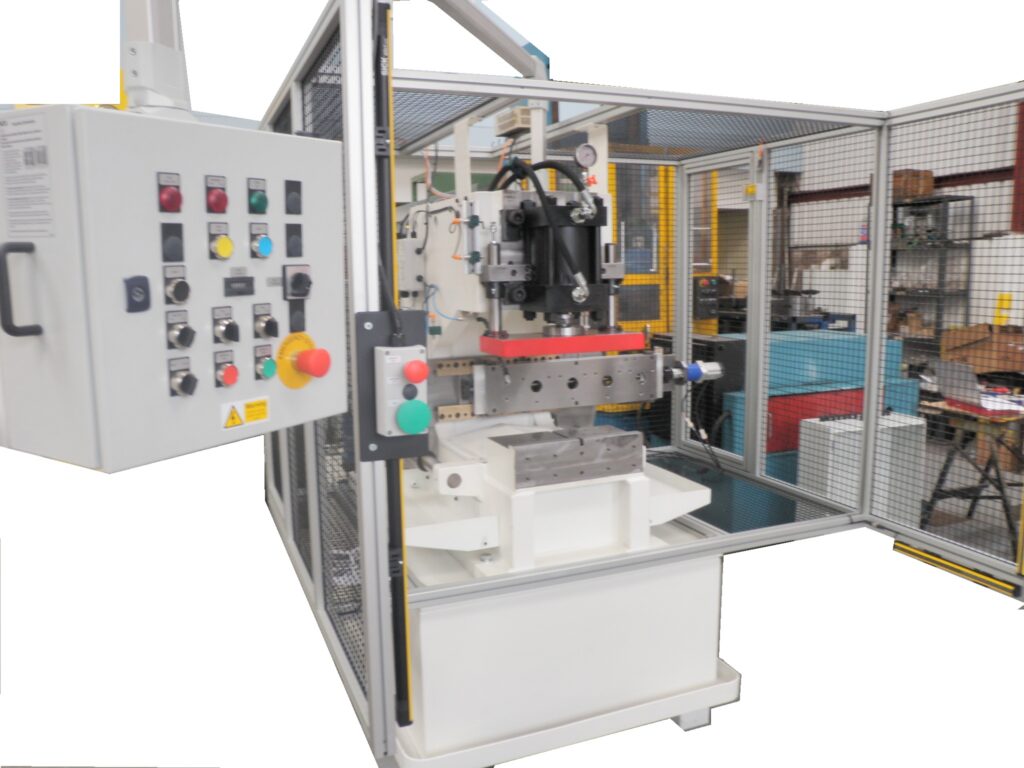

The ‘Exhaust Tooling Ltd’ model CFR with shuttle machine incorporates a hydraulic clamp (vice) with additional rear ram and shuttle assembly allowing complex manipulation of the end of tubes depending upon the type and design of tools used.

The Ram Shuttle can have up to 6 stations for multiple forming operations.

It can also incorporate a trimming blade to cut the component to required form and length and also a small notching tool incorporated into the final forming tool.

The machine can also be fitted with a state of the art lubrication assembly that atomises lubrication along the ram tooling to ease forming and prevent burrs.

Orbital Spinning

The Exhaust Tooling Ltd ‘OS’ Machine is a self contained unit and has two individually controlled hydraulic cylinders, one to clamp the part, the other a ram for forming or segmented tooling operations, and a rotary spindle for spinning.

It also features a hydraulically powered lower vise jaw slide, which can be selected to move out towards the operator at the end of every operation, until cycle start signals its return.

The ‘F’ Head has a single action horizontal ram and a vertical clamping vise. The vise can be easily removed if not required. The ‘F’ Head will accept all ‘E’ type forming tooling for vise – ram forming plug expanding, ring reducing, flaring or coning. Also with the rotary spindle within the horizontal ram rotary flaring, rotary bead forming, etc. can be performed.

With the vise removed the head will accept large or standard size ‘C’ type expanding, reducing or slotting tooling.

Slotting

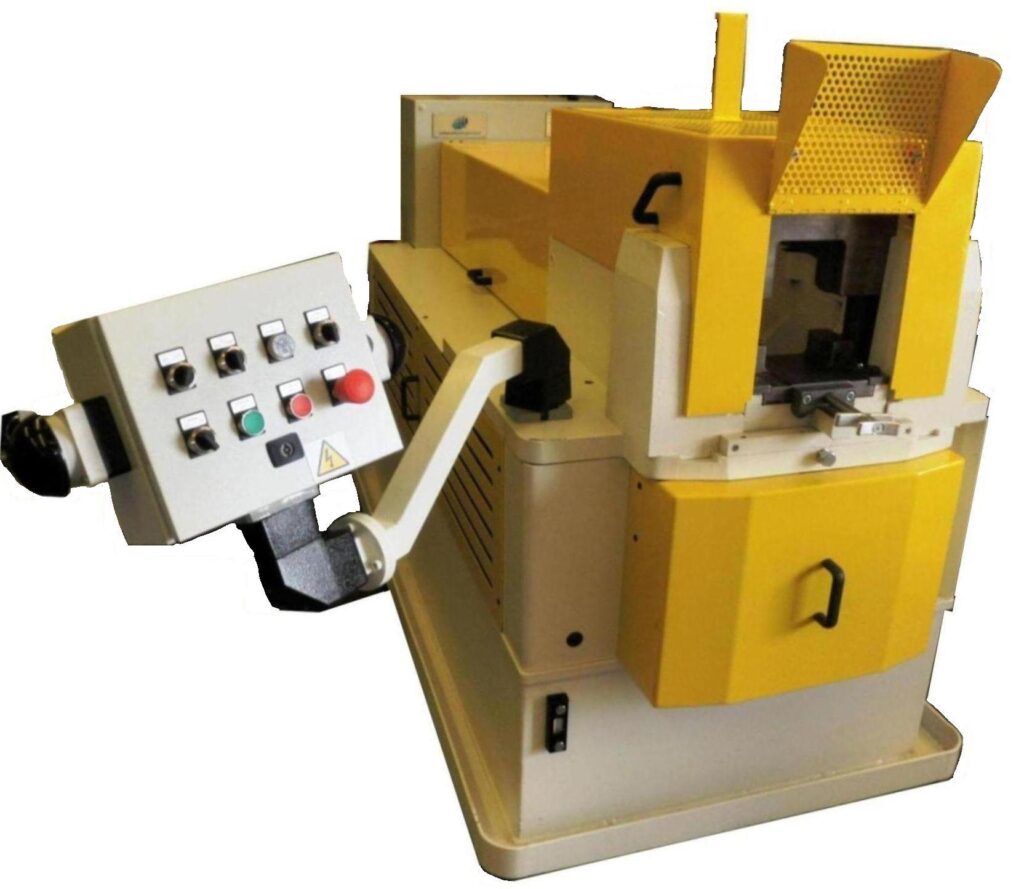

The ETL Slotter 75 Tube End Form Machine is designed and manufactured for the sole use of producing different shaped slots in the ends of thin wall (up to 3mm wall thickness) automotive pipes.

The ETL Slotter model is a basic tube end forming machine for producing slots or notching using the interchangeable tooling supplied by ETL.

The machine is a compact, self-contained unit with the motor, drive and all hydraulic components mounted on top of the oil tank for ease of access. The Slotting head is mounted on a welded frame

And must use the designated tooling for each designed component.

The head is not adjustable. It works on a fixed stroke (14mm each way). The ETL tooling is designed for this specific stroke.

Customised

Depending on customer requirements and specifications ETL can Design, Manufacture and Build a machine that incorporates multiple aspects of the standard machines above, in order more effectively and efficiently tube end form. This includes a selection of differing heads such as C-EF, IO-C or heavy duty and large sale applications for machines for example the Heavy Duty Orbital Spinning, Muffler Seaming* and Baffle Stuffing Machines.

Whilst some applications may in fact require light duty machines, we are also able to offer such as BM50 Beading Machinary.

Other more specialist applications can provide opportunity to show case our adaptability in manufacturing specialised such as a Tubes to Manifold Sizing Machine

Spares

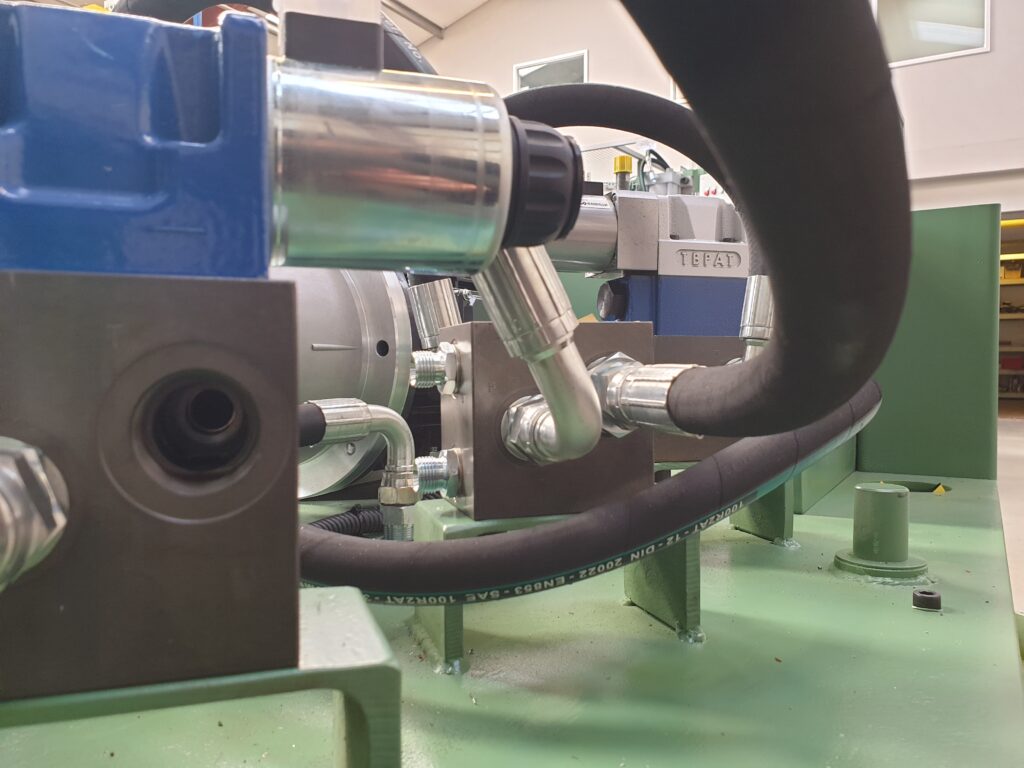

Through providing such a varied range of new machines, we support an extensive range of replacement parts for ETL, Eagle Precision and Deltic Machines supplied from stock or manufactured to order including: replacement parts, hydraulics, hydraulic seals including replacement head seal kits.

Refurbished Machinery

We offer refurbished machines at a lower price than brand new, alongside used machinery. Take a look at our dedicated page for previous refurbishments and our current available used machines.