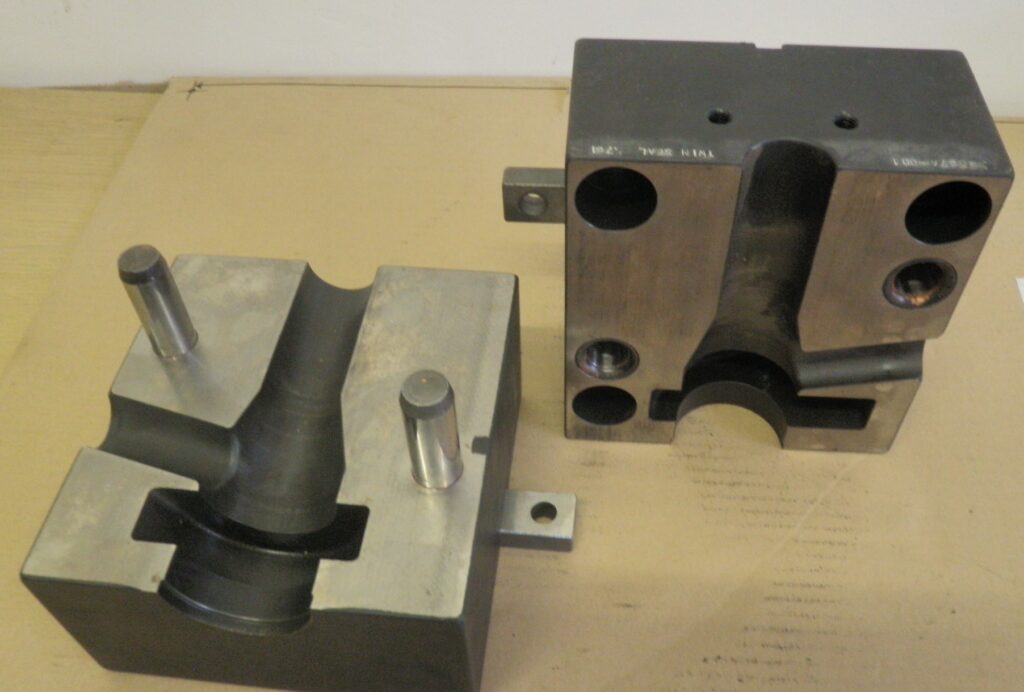

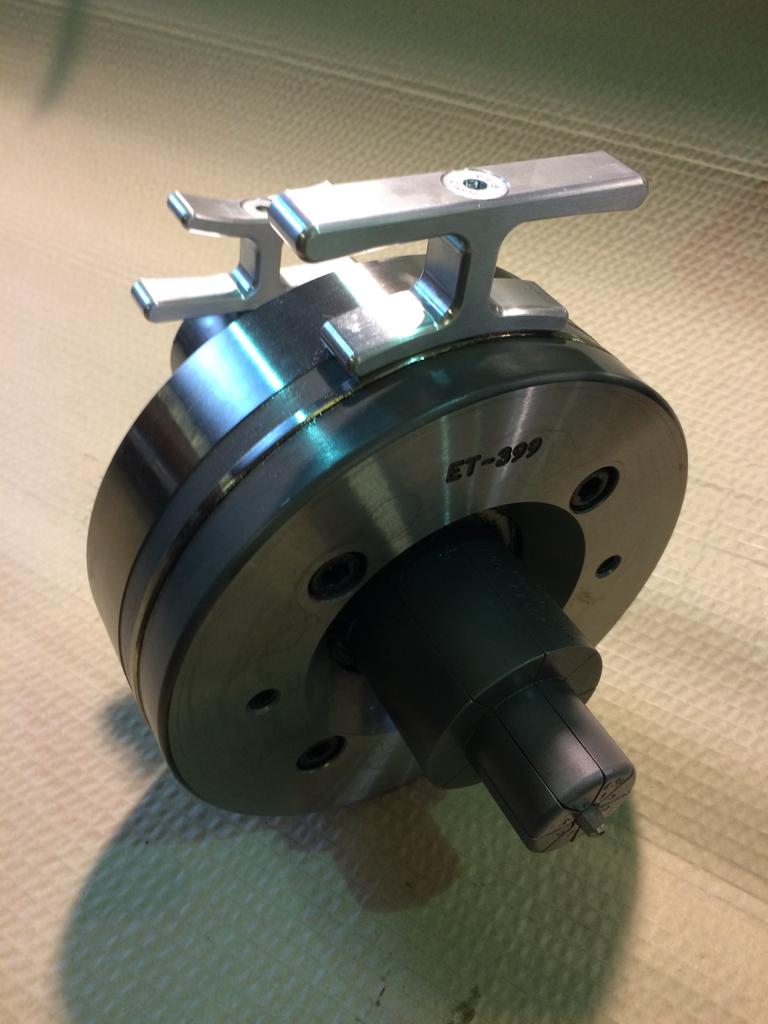

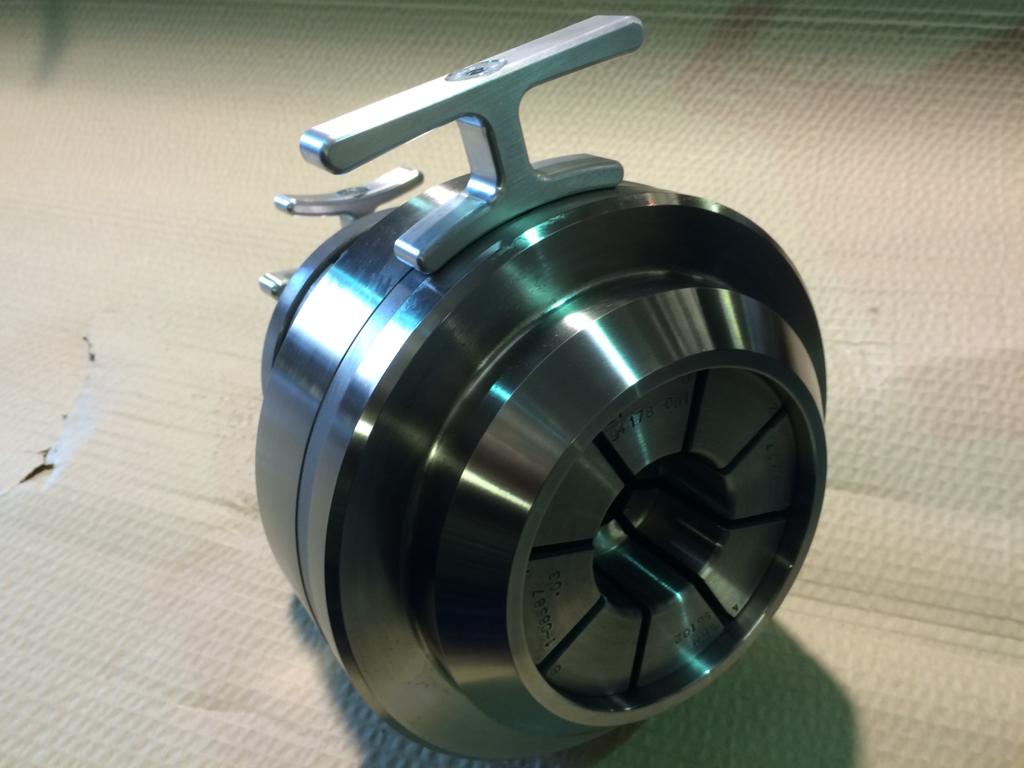

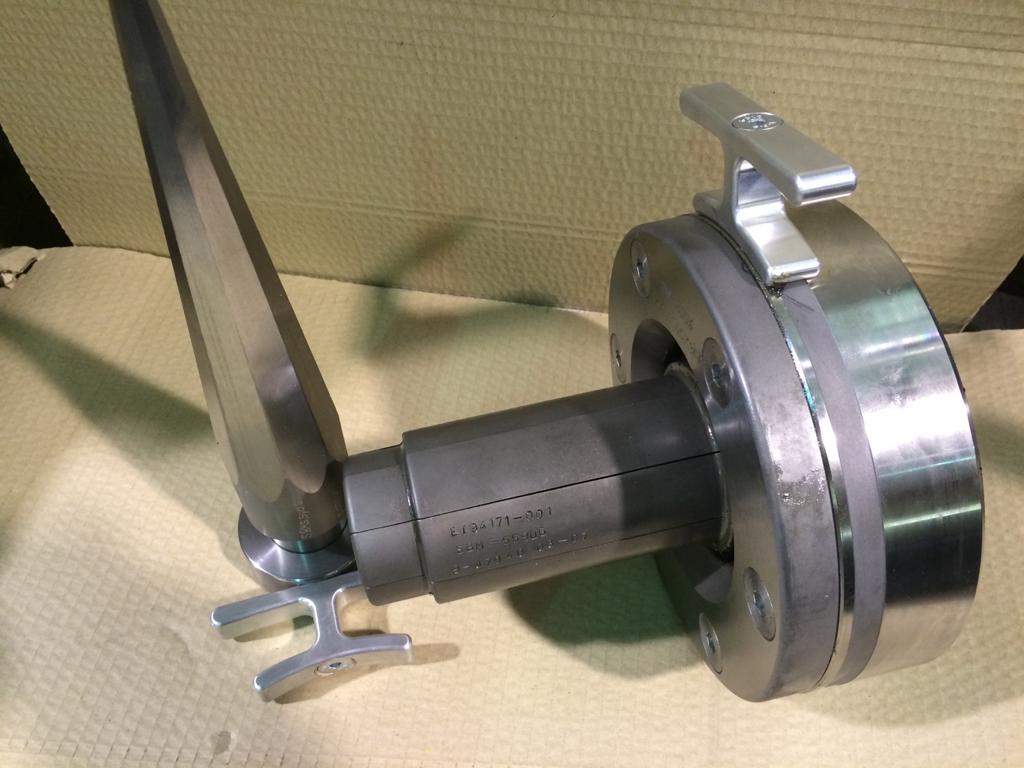

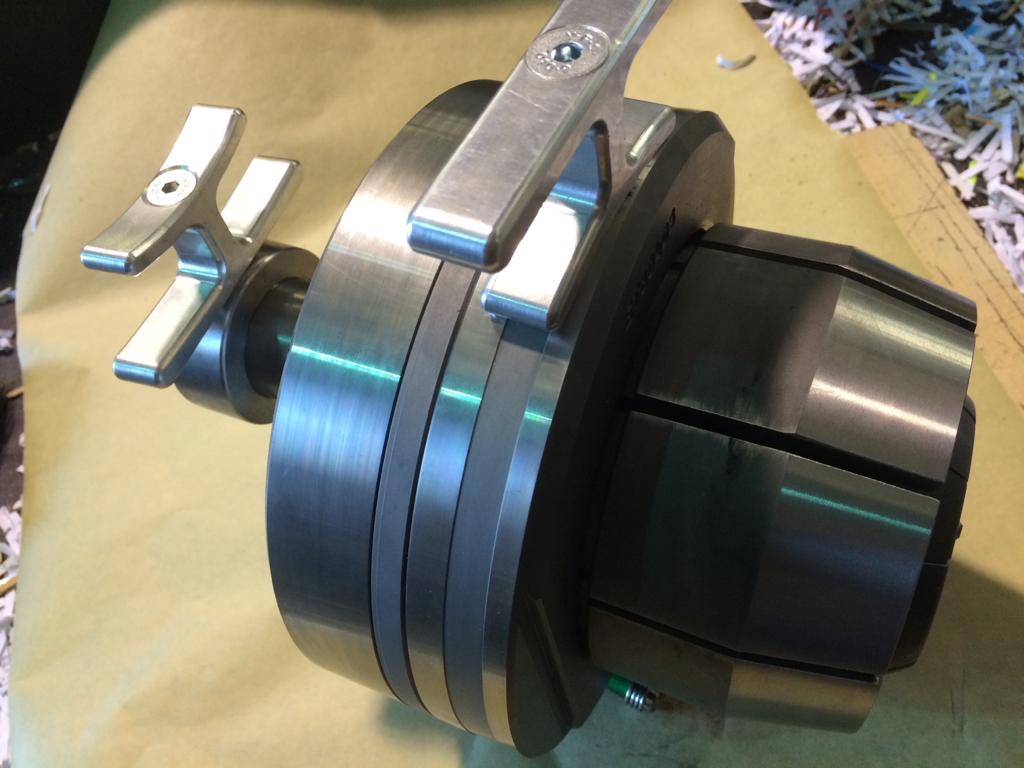

C Tooling

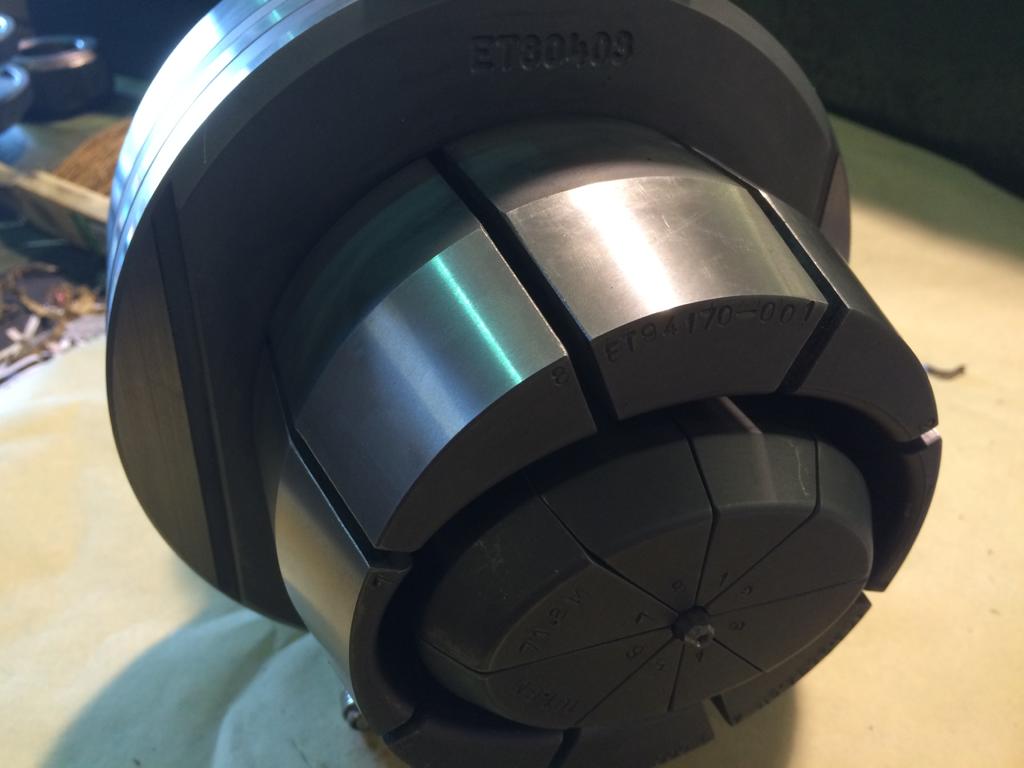

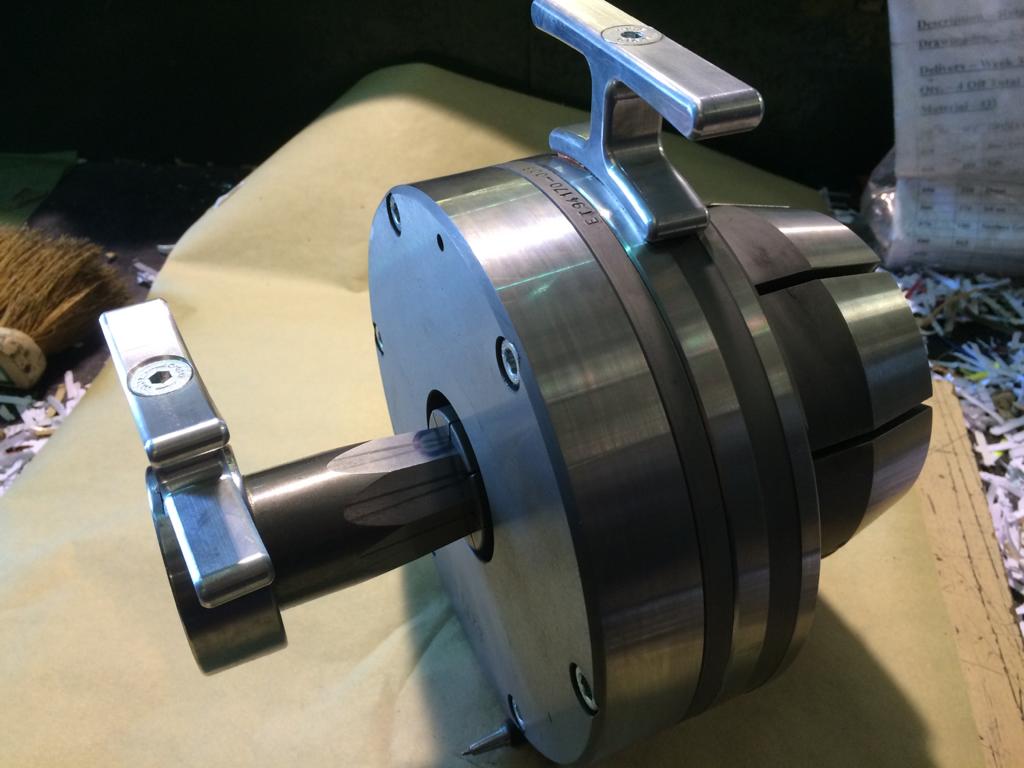

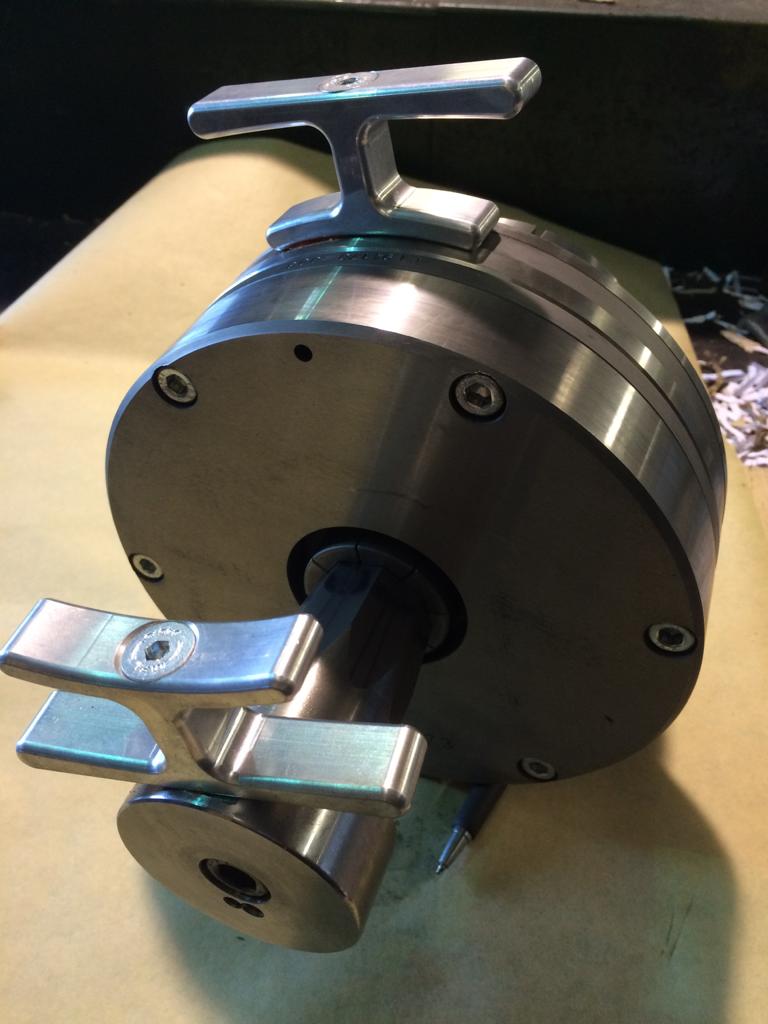

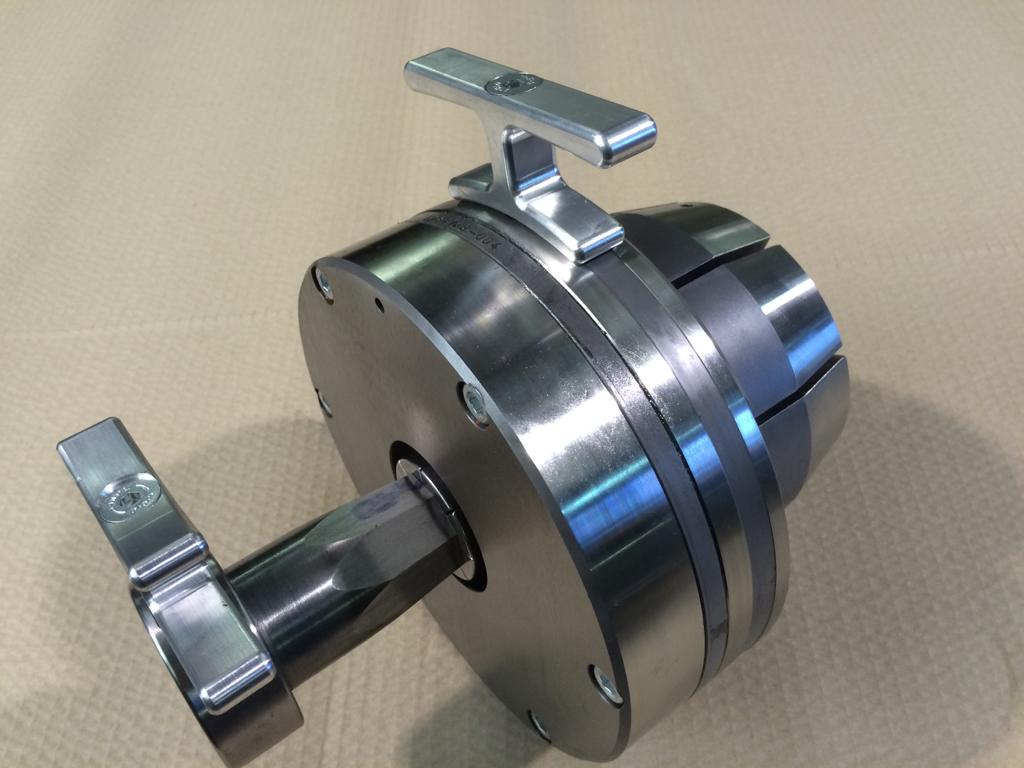

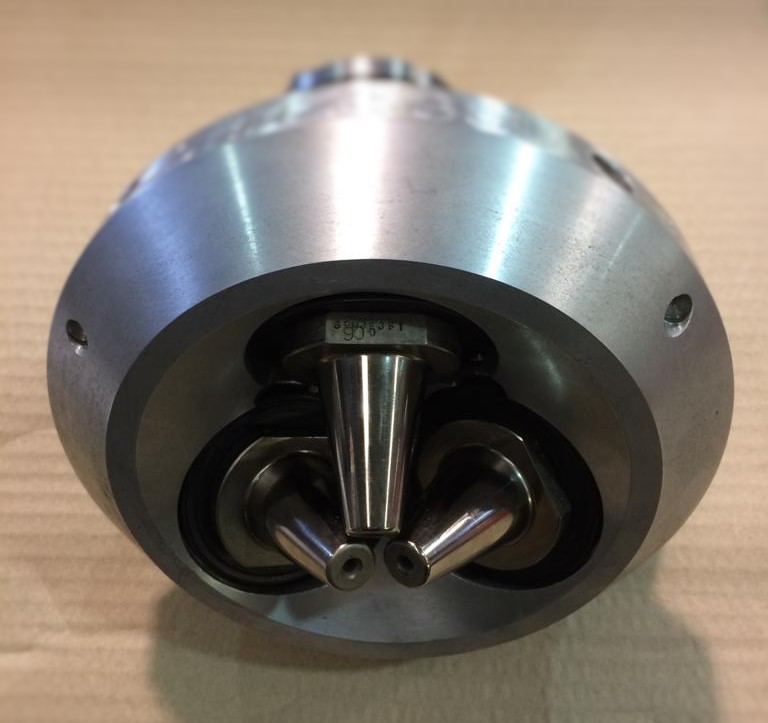

“C-Type” tooling is extremely versatile and can be ordered as a standard sizes from stock or custom requirements manufactures on a lead time. C tooling includes expanding, reducing and slotting tools, all in a “Drop-In” simple installation, interchangeable in all ETL and Eagle Precision “C”, “D”, “E”, “F” OR “EF” machines. C finger assembly options feature a Barrel Assembly (that can be in hardened steel or with a lightweight, aircraft grade, aluminium option perfect for if the tool are regularly changed), extremely durable segmental fingers requiring a tapered mandrel to expand to size. These tools may be 6 or 8 segments depending on the sized diameter. Otherwise, C jaws reduce pipe diameters requiring a tapered reducing ring.

Whilst these tools can either expand or reduce, when used together in a “D” machine, a very accurate sizing can be achieved by taking materials past their elastic limit.

Browse our sizing chart for standard C tooling here.

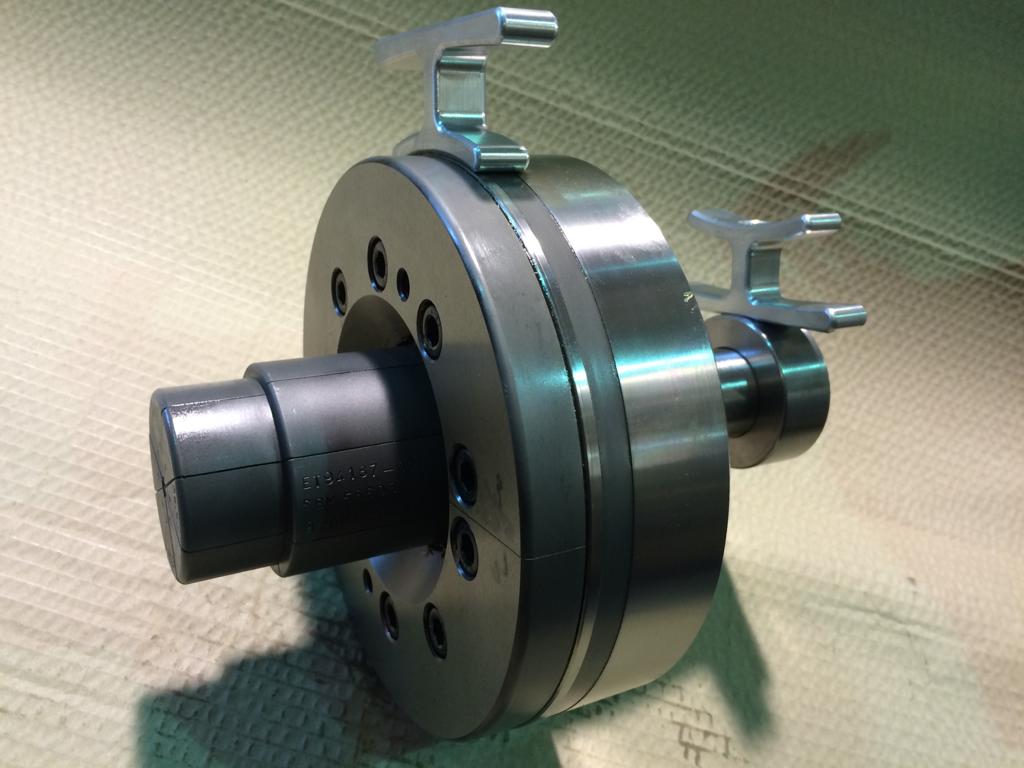

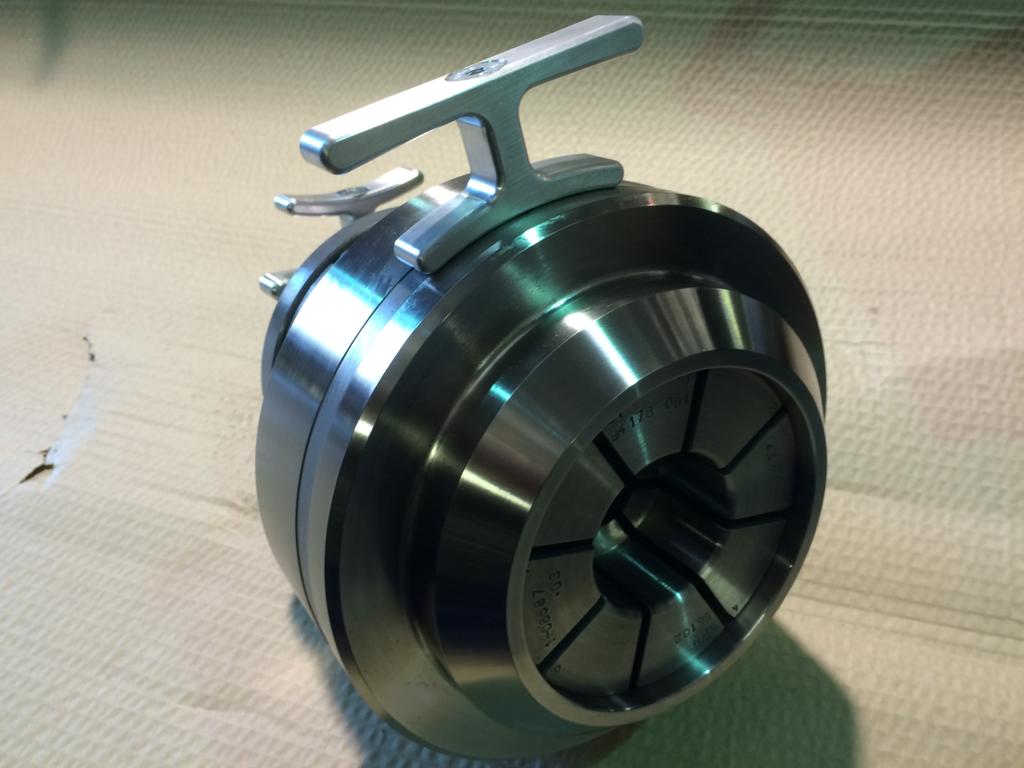

IO Tooling

“IO” tools are designed for a quick change “Drop-In” loading into an ETL and Eagle Precision IO machines. IO have advantages over IO by allowing a much greater accuracy in sizing to a nominal diameter as gaps between segments are smaller than C, whilst the Jaws and Fingers are offset allowing for a smoother, more even flow of metal over the segments, generally eliminating the need to rotate the part and recycle the machine. Functions include sizing two different diameters, forming an annular bead, produce flared end and emboss a projection (such as dimpling), these can be performed individually or all at one if necessary. IO tooling assemblies can be supplied in standard hardened steel barrel assemblies, or a lightweight option in aircraft grade aluminium.

Due to the accurate nature of the IO tools, each tool must be manufactured to customer specification, accounting for sizing needs, pipe wall thickness and required nominal diameters. Extremely customised application may be produced such as ram tooling

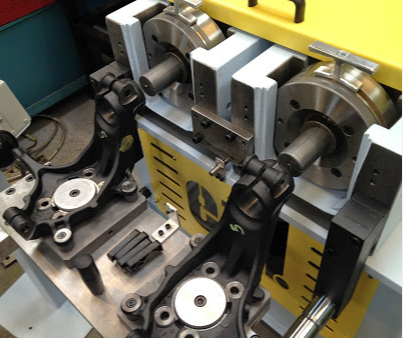

Orbital & Ram Tooling

This type of tooling compatible in “E”, “F” and “EF” machines. Other tooling is available for shuttle machines, C-Frame machines, BM50 machines and IO machines. These tool create extremely precise and accurate tube end forms for a multitude of applications. With obitial forming mating ends can be produced to resemble a “ball-joint” allow for adjustment in custom, high performance and low-quantity production exhaustive systems for example that once in the correct position can be clamped to provide a sturdy, airtight seal. Other applications include extreme sizing operations between different pipe diameters, or to form a bead providing clamping purchase for hoses etc.

Lockseam Tooling

Specialist Tooling